Working principle of dowty retarder system

The dowty retarder detection device uses a digital servo control system (Figure 2), uses a single-chip closed-loop control to load and collect data, and uses a hydraulic device to simulate the force and speed generated by the train wheels when they pass the track. It is very useful in use. Convenient, high degree of automation and fast response speed.

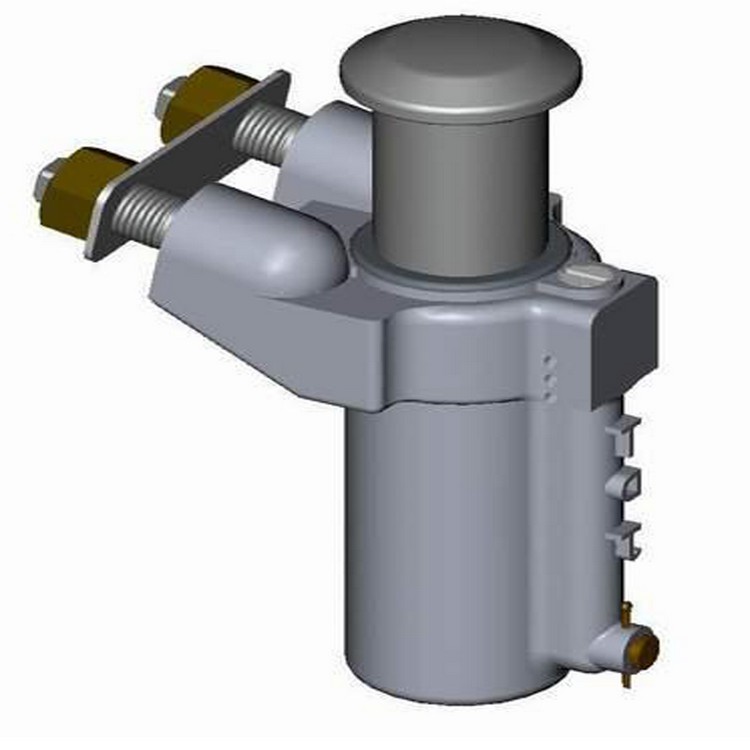

As long as the dowty retarder is installed on the detection device, the device is locked by the clamping mechanism, and then the dowty retarder is pressurized by key operation, and sampling control is performed at the same time, so as to display the relevant performance parameters of the dowty retarder. Through the analysis of these data, Judge whether the retarder is qualified.The device can complete the detection work in a short time of 0.06 seconds. Using the action of the oil pump, the accumulator stores energy, and then generates a force of about 2 tons on the force surface of the dowty retarder with a diameter of about 40mm to form a pressure of about 20mp. Reproduce the situation of wheel rolling, and the obtained detection data is accurate and effective.

It is worth mentioning that the weight of the device is about 100kg and the volume is small. After the optimized design, the product is very convenient to use. The device can be operated with only a few buttons, which is fast and accurate.