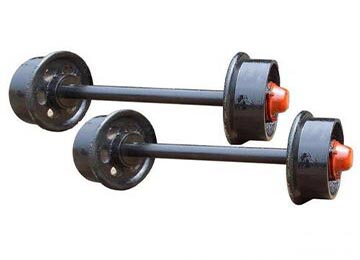

Several Types Of Failure Of Mine Wagon'S Wheelsets

Beacuse of the wheelset's bad working environment, flaws in design, and improper management, the service life of wheelsets is too short. In the investigation, Wheelsets need to maintained when they are used downhole for six months underground in general. In fact, the working load and running speed of the mine wagon's wheelset downhole is not high. The failure of wheelset is not caused by fatigue of the bearing.

The main failure types are:

1. Sealing failure. When muddy water with acid and alkali components enters the bearing raceway through the gap of the seal, it will cause the steel ball to be blocked by the dust and fails.

2. Bearing failure. Because the bearing is stuck and does not turn, causing the relative rotation between the inner ring or outer ring of the bearing and the axle or hub, the axle is seriously worn and the stress concentration occurs, and the axle is broken under the action of the external impact load, and the inner circle of the hub is caused. Severe wear causes the gap between the wheel hub and the bearing outer ring to increase, causing the wheel to oscillate excessively and fail.