Skillful "cure" the dowty retarder

A batch of dowty retarder that were about to be scrapped were transported to the repair room of the retarder repair area in the comprehensive workshop of Xiangtangxi Station. The 49-year-old dowty retarder repairman Wan Xu immediately led the repair team to get busy.

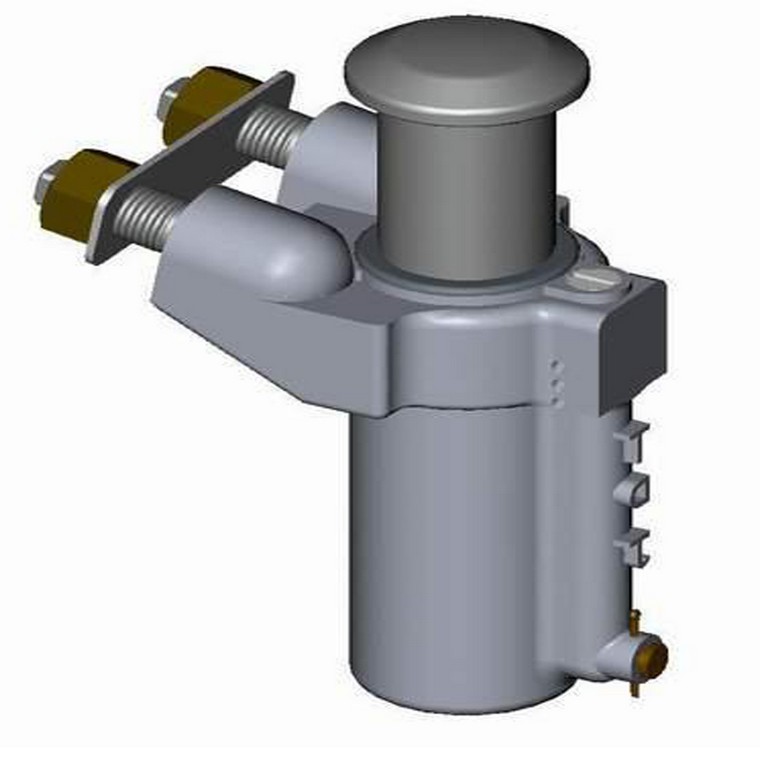

The Xiangtangxi Station Marshalling Yard has 56 strands and 10247 dowty retarder have been installed. As the main speed regulating equipment of the marshalling station, the retarder plays an extremely important role in ensuring the safety of shunting operations. Due to the large losses in daily production and use, the dowty retarder has become a "larger" in station costs. In the past three years, the average annual maintenance cost of the dowty retarder at this station is about 200,000 yuan. Since the launch of the theme promotion activity of “Contribute to Saving Costs and Contribute to Reform and Innovation, Make New Contributions to Reform and Innovation”, the comprehensive workshop has established a maintenance team led by Wan Xu to vigorously carry out technical research.

I remember the number, model, performance, and location of the dowty retarder in the marshalling yard. As long as I step on the dowty retarder and listen to the sound and foot feeling, I can judge the dowty retarder. Can't use it, is it good? "Wan Xu has been working in this position for 28 years since he entered the road in 1992, and he has already understood the standard and performance of the dowty retarder.

Since the seal cover circlip of the dowty retarder jack cylinder assembly is easier to break and difficult to disassemble, in the past, most workshops were scrapped. For this reason, the members of the research team brainstormed and used their brains to run-in and adjust the turnbuckle with the intact sealing cover, which effectively solved the problem of internal thread tripping of the cylinder assembly.

Wan Xu and the team members also found that the removed top shell is often scrapped due to internal anti-offset or bending or fracture of bolts. So, after repeated attempts, they finally came up with a solution: first soak the top shell with oil to lubricate it, and then use a flat spatula to pick out the bent or broken anti-stroke pins or bolts.

Since the beginning of this year, under everyone's careful consideration and patience, nearly a thousand dowty retarder that are about to be scrapped have been "cured" in their skillful hands and "employed" again, saving a total of more than 30,000 yuan.