Do a health check for the dowty retarder

Recently, 6 employees of the dowty retarder team of the comprehensive workshop inspected the 7 controllable roofs of the three stations of the station and found that the 5 controllable roofs could not be used after power was supplied. The foreman Guo Haizhong analyzed that the solenoid valve was immersed in water and caused the shell to be soaked. If there was ice accumulation in the solenoid valve, everyone immediately split up, disassembled the solenoid valve to take out the ice accumulation, and replaced the faulty valve.

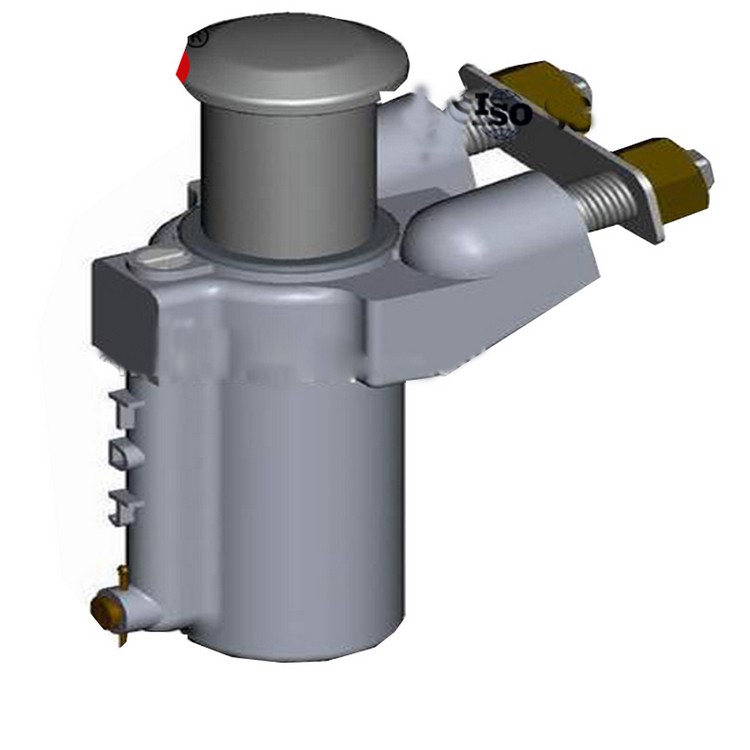

The microcomputer controllable top is a kind of dowty retarder. It is controlled by the computer to connect the cable and the solenoid valve controls the sliding cylinder assembly, which plays a role in regulating the speed of the vehicle. Its internal mechanism is more precise and it is more difficult to maintain than the ordinary retarder.

In spring, the temperature changes day by day and the night freezes, and some equipment is prone to "sickness" due to temperature differences, causing hidden dangers to transportation and production safety. In order to effectively improve the quality of equipment and ensure driving safety, I set up a special leading group on the premise of preventing and controlling the epidemic situation to conduct on-site investigations and investigations for dowty retarder hidden dangers, do a solid reorganization work, and organize a comprehensive workshop to slow down. The team shortened the inspection and maintenance cycle and increased the inspection efforts to ensure that the on-site equipment "is treated promptly if there is a disease, and is healthy without any disease."

Snow residue in winter meets continuous heavy snowfall in spring. There are serious snow in the area of the dowty retarder line in the three-time operation and the passenger station. The snow melted water enters the pit during the day and freezes at night, and the dowty retarder is easy to cause hard roof due to the freezing in the shell. , Sliding cylinder failure and other problems, daily due to the accumulation of water, the number of controllable roof repairs increases suddenly, which directly affects driving safety.

The retarder work area strictly inspects and maintains dowty retarder equipment, and regularly conducts health examinations for 11936 dowty retarder devices in the station, ensuring that the station's 2842 computer-controlled jacking devices are 100% qualified, ensuring the quality of the equipment and laying a solid foundation for safety.